UK agent and local assistance of Tecnofer

Tecnofer are industry leaders in the production of innovative and tailor made plants for plastic recycling and waste treatment. Tecnofer are ambassadors of sustainable technology for the recycling and valorisation of waste. Bringing low environmental impact innovations all around the world, transforming waste raw materials into new resources.

Tecnofer was born in 1976 from a very cutting-edge idea for that time: designing technologies capable of turning waste into new resources. Tecnofer are a symbol of innovation in the field of plastic recycling technologies.

www.tecnofer.biz

Tailor-made Design

Thanks to consolidated know-how Tecnofer offers tailor-made solutions combining quality and flexibility, accompanying the customer in every phase of the project.

Sustainable Development

Tecnofer apply production and business models inspired by the principles of Circular Economy to protect people and contribute to the protection of the planet.

Laboratory, Test Area & T-Lab

Tecnofer test and maximize the quality of the product to be processed and the efficiency of Tecnofer technology, which the customer can experience first hand.

Tecnofer plants can treat…

PET Bottles

![]()

PE-PP Film, PP Big bags

HDPE-PP Plastics

![]()

Packaged Products

Pulper’s Reject

![]()

Absorbent Products

Tecnofer Machines

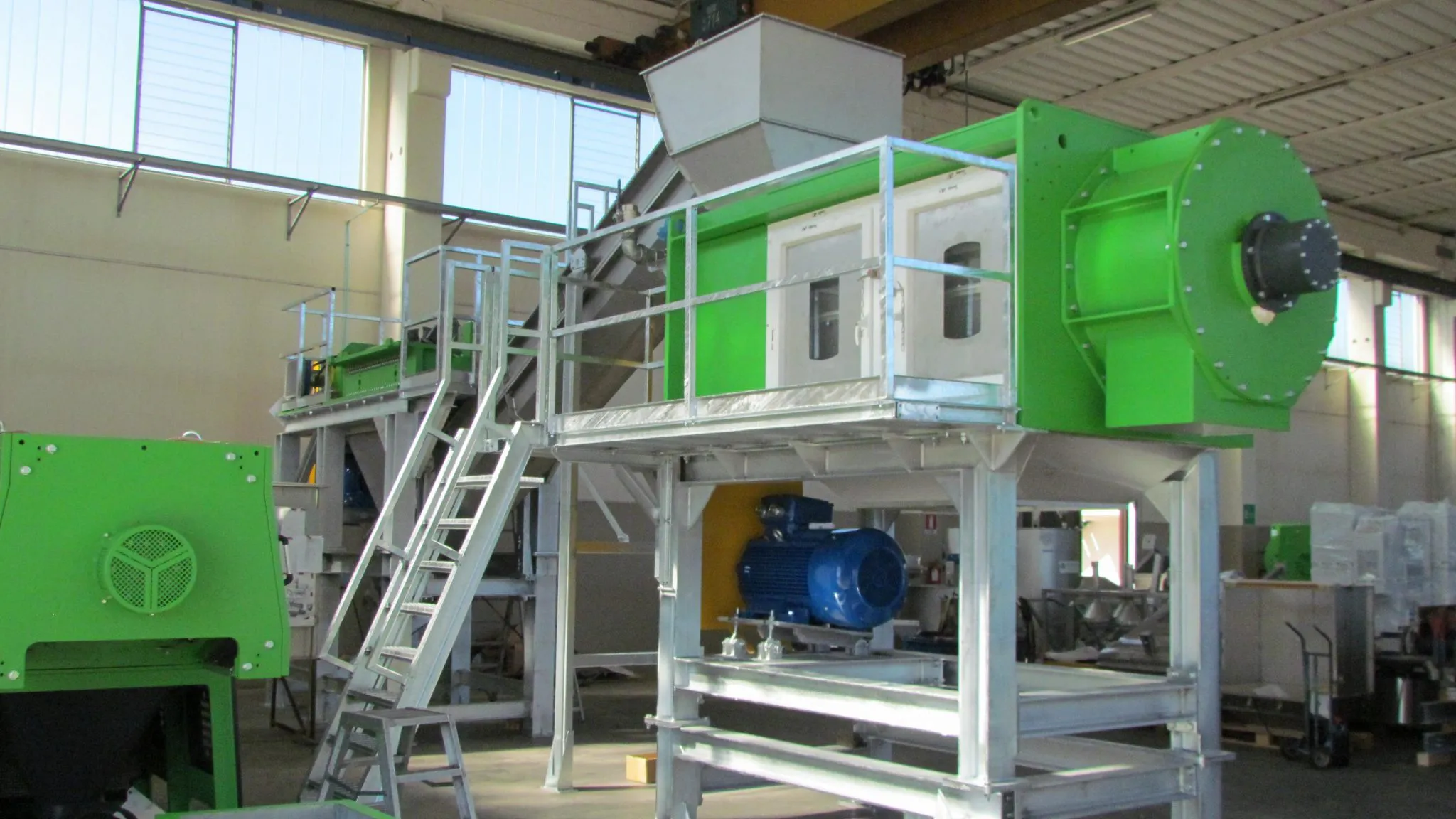

Shredder

The single shaft industrial shredder is a versatile machine suitable for a primary grinding of waste materials with high contamination.

Pulper Friction Washer

The friction washer for pulper rejects principle is to separate the fibers and recycled fiber from the plastic fraction with a centrifugal action combined with water.

Depacker

Separates the waste products from its packaging. It can be equipped with different feeding and extracting systems in function of the waste product to be depacked.

Squeezer

The waste squeezer is installed at the end of the film washing lines for drying the material. The dewatering screw press system is based on the mechanical squeezing.

Organic Squeezer

The organic waste squeezer is a continuous squeezing system designed for the partial dehydration of wet waste coming from separate collection.

Pulp Shredder

The single shaft pulp shredder processes rejects coming from a trommel or a from a discontinuous system (poire / pressurized secondary pulper).

Plastic Friction Washer

The plastic friction washer has been designed to wash highly contaminated rigid or flexible plastic flakes which come from a primary shredder or from a grinder.

Hot Treatment Unit

The hot washer for plastic is a machine studied for processing all kinds of hard plastic flakes like PET, HDPE, PP, ABS & PVC.

Pre-washing tank

Separates plastic materials from heavy contaminants, by settling stones and heavy material that could damage the following machines of the washing process.

Washing tank

The washing tank has the function to separate by density the polyolefin plastic flakes from the heavy sinking plastic flakes.

Grinder

The plastic grinding machine is used to grind flexible or rigid materials with or without water.

Fluid bed dryer

The fluid bed dryer is used for removing the residual moisture contained in the plastic flakes after the dewatering system.

Film storage silo

Used in different areas of the recycling plant, more frequently at the end of washing line to stock and dose the plastic flakes to be fed into the extruder.

Dynamic centrifuge

The dynamic centrifuge is a centrifugal plastic washer used in different applications to wash, dry and separate many flexible or rigid materials.

Bale breaker

The bale breaker is used for opening the bales of pressed HDPE, PP and PET bottles.

Find out more about Tecnofer

Industry Sectors

Plastic Waste Recyclers

The business goal of plastic waste recyclers is giving new life to disposal plastic fraction, turning it into useful, functional and high quality products. Tecnofer is an important part of their ecosystem, becoming a strategic and technological partner in recycling sector. The solutions offered are tailor-made and designed on the specific plastic fraction to recycle.

Food Industry

What are the causes of food waste? Inside production processes, we can find labelling errors, packaging discrepancies, packaging not suitable for maintaining the freshness of the product. In distribution, otherwise, we can find expired or unsold products. Goods that have these kinds of problems are full-fledged wastes ready to be disposed and sent into landfill. This involves a cost for companies, as well as a significant waste of resources.

Paper mill waste solutions

For over 45 years Tecnofer has been designing and manufacturing solutions for the valorisation of pulper’s rejects. Thanks to our experience and to the continuous study of ecological solutions for different kinds of sectors, allowed us to develop a specific solution for paper mill industry.

Animal Feed Industry

Integrating part of the waste resulting from the food industry destined for human consumption into animal feed is the next achievement of sustainability. A study of the European Union demonstrates this and underlines how only replacing 10% of feed ingredients with ingredients coming from human food waste lead to significant benefits, both in nutritional terms for the animals and in terms of environmental sustainability.

Biogas Power Plants

Reducing the negative human impact on the planet by maintaining a solid and stable economy is an unparalleled challenge. There are solutions available though, and today more than ever these solutions are becoming the first choice for many companies in different sectors.